GOLDENGRIP

Premium Submersible Winding Wires for Maximum Motor Life

GOLDENGRIP

Premium Submersible Winding Wires for Maximum Motor Life

High Temperature Submersible Winding Wires

Goldengrip a Patented winding wires are designed to deliver exceptional reliability and performance in domestic and industrial submersible motors.

With unmatched thermal endurance, mechanical strength, and high insulation resistance, Goldengrip helps motors operate efficiently and safely, even under the most critical conditions.

VFD Compatible

Reduce stator winding area

Low Water Absorption

Provide Long Life to the Motor

Lower derating at higher temperature

Increase Efficiency

Motor can take more load compare to Normal Winded motor (Over-size Pump on Motor)

Motor will survive better in case of High/Low Voltage as wire can take more Amps.

Motor will survive better in case Dry Motor Run (Leakage of Water in Motors)

Benefits to Submersible Motor

Goldengrip ensures your submersible pump motor lasts longer and runs more efficiently, especially in demanding environments.

Special Features of Goldengrip

Enjoy these added advantages with every purchase

EC Grade High-Purity Copper

Goldengrip uses EC grade copper with a minimum purity of 99.95% (ETP Copper). It is highly annealed, allowing for smooth, flexible, and efficient motor winding during assembly.

High insulation resistance

It offers superior insulation resistance, with VR values up to 400% higher than standard BOPP or PVC wires. These high insulation levels are consistent even at elevated temperatures of 27°C and 90°C.

Temperature Range

Goldengrip performs exceptionally across a wide temperature range, withstanding up to +200°C for short periods and operating continuously from -40°C to +140°C.

Higher Mechanical Strength

The wire is designed for high mechanical strength, featuring excellent tear resistance due to bi-axial polypropylene orientation. Its golden insulation delivers better tensile strength compared to polyester and BOPP.

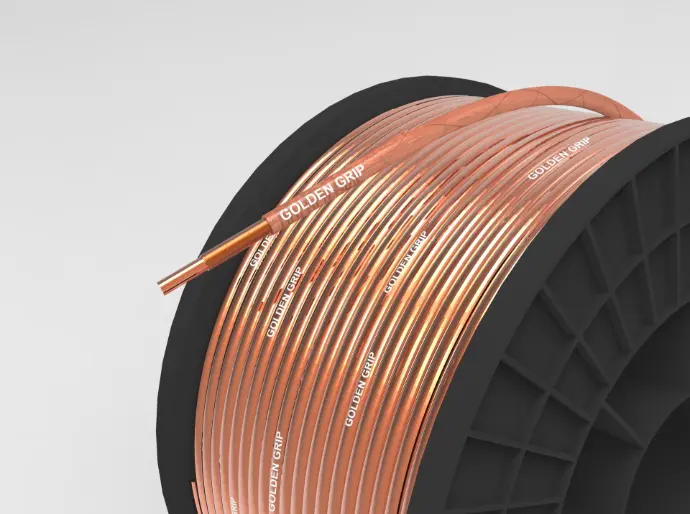

Available Packing Options

Goldengrip winding wires are available in standard coil sizes for flexible usage:

Packing Option

Box Packing

Spool Packing

Goldengrip Winding Wires For Submersible Pump Motors

(Tested As Per IS 8783)

| Copper Cross Section Area (mm²) | Conductor and No. of Strands (Design) | Copper Dia. (mm) | Wire OD (mm) | Nominal Insulation Thickness (mm) | Total Weight/Km (kg) | CR Max at 20°C (Ohm/Km) | Elongation (%) | Max Coil Length (Meters) | Packing Type |

| 0.38 | 1 x 0.7 mm | 0.7 | 1.2 | 0.25 | 4.26 | 45.7 | 28 | 1500 | PVC Drum |

| 0.5 | 1 x 0.8 mm | 0.8 | 1.3 | 0.25 | 5.38 | 35 | 28 | 1500 | PVC Drum |

| 0.64 | 1 x 0.9 mm | 0.9 | 1.4 | 0.25 | 6.63 | 27.6 | 29 | 1500 | PVC Drum |

| 0.79 | 1 x 1.0 mm | 1 | 1.5 | 0.25 | 8.05 | 22.4 | 30 | 1500 | PVC Drum |

| 0.95 | 1 x 1.1 mm | 1.1 | 1.6 | 0.25 | 9.6 | 18.5 | 30 | 1500 | PVC Drum |

| 1.13 | 1 x 1.2 mm | 1.2 | 1.7 | 0.25 | 11.29 | 15.5 | 31 | 1500 | PVC Drum |

| 1.33 | 1 x 1.3 mm | 1.3 | 1.8 | 0.25 | 13.12 | 13.2 | 32 | 1500 | PVC Drum |

| 1.54 | 1 x 1.4 mm | 1.4 | 1.9 | 0.25 | 15.1 | 11.4 | 32 | 1500 | PVC Drum |

| 1.77 | 1 x 1.5 mm | 1.5 | 2.5 | 0.5 | 18.95 | 9.95 | 32 | 1500 | PVC Drum |

| 2.01 | 1 x 1.6 mm | 1.6 | 2.6 | 0.5 | 21.28 | 8.75 | 32 | 1500 | PVC Drum |

| 2.27 | 1 x 1.7 mm | 1.7 | 2.7 | 0.5 | 23.75 | 7.75 | 32 | 1500 | PVC Drum |

| 2.54 | 1 x 1.8 mm | 1.8 | 2.8 | 0.5 | 26.36 | 6.91 | 32 | 1500 | PVC Drum |

| 2.84 | 1 x 1.9 mm | 1.9 | 2.9 | 0.5 | 29.11 | 6.2 | 32 | 1500 | PVC Drum |

| 3.14 | 1 x 2.0 mm | 2 | 3 | 0.5 | 32 | 5.6 | 33 | 1500 | PVC Drum |

| 3.46 | 1 x 2.1 mm | 2.1 | 3.1 | 0.5 | 35.03 | 5.08 | 33 | 1500 | PVC Drum |

| 3.8 | 1 x 2.2 mm | 2.2 | 3.2 | 0.5 | 38.2 | 4.63 | 33 | 1500 | PVC Drum |

| 4.15 | 1 x 2.3 mm | 2.3 | 3.3 | 0.5 | 41.51 | 4.23 | 33 | 1500 | PVC Drum |

| 4.52 | 1 x 2.4 mm | 2.4 | 3.4 | 0.5 | 44.96 | 3.89 | 33 | 1500 | PVC Drum |

| 4.91 | 1 x 2.5 mm | 2.5 | 3.5 | 0.5 | 48.54 | 3.58 | 33 | 1500 | PVC Drum |

| 5.31 | 1 x 2.6 mm | 2.6 | 3.8 | 0.6 | 53.35 | 3.31 | 34 | 1500 | PVC Drum |

| 5.73 | 1 x 2.7 mm | 2.7 | 3.9 | 0.6 | 57.25 | 3.07 | 34 | 1000 | PVC Drum |

| 6.16 | 1 x 2.8 mm | 2.8 | 4 | 0.6 | 61.28 | 2.86 | 34 | 1000 | PVC Drum |

| 6.61 | 1 x 2.9 mm | 2.9 | 4.1 | 0.6 | 65.46 | 2.66 | 34 | 1000 | PVC Drum |

| 7.07 | 1 x 3.0 mm | 3 | 4.2 | 0.6 | 69.77 | 2.49 | 34 | 1000 | PVC Drum |

| 7.55 | 1 x 3.1 mm | 3.1 | 4.3 | 0.6 | 74.23 | 2.33 | 35 | 1000 | PVC Drum |

| 8.04 | 1 x 3.2 mm | 3.2 | 4.4 | 0.6 | 78.82 | 2.19 | 35 | 1000 | PVC Drum |

| 8.55 | 1 x 3.3 mm | 3.3 | 4.5 | 0.6 | 83.56 | 2.06 | 35 | 1000 | PVC Drum |

| 9.08 | 1 x 3.4 mm | 3.4 | 4.6 | 0.6 | 88.43 | 1.94 | 35 | 1000 | PVC Drum |

| 9.62 | 1 x 3.5 mm | 3.5 | 4.7 | 0.6 | 93.44 | 1.83 | 35 | 800 | PVC Drum |

| 10.18 | 1 x 3.6 mm | 3.6 | 5 | 0.7 | 100.03 | 1.73 | 36 | 800 | PVC Drum |

| 10.75 | 1 x 3.7 mm | 3.7 | 5.1 | 0.7 | 105.35 | 1.64 | 36 | 800 | PVC Drum |

| 11.34 | 1 x 3.8 mm | 3.8 | 5.2 | 0.7 | 110.81 | 1.55 | 36 | 800 | PVC Drum |

| 11.95 | 1 x 3.9 mm | 3.9 | 5.3 | 0.7 | 116.41 | 1.47 | 36 | 800 | PVC Drum |

| 12.57 | 1 x 4.0 mm | 4 | 5.4 | 0.7 | 122.15 | 1.4 | 37 | 750 | PVC Drum |

| 13.2 | 1 x 4.1 mm | 4.1 | 5.5 | 0.7 | 128.03 | 1.33 | 37 | 750 | PVC Drum |

| 13.85 | 1 x 4.2 mm | 4.2 | 5.6 | 0.7 | 134.05 | 1.27 | 38 | 750 | PVC Drum |

| 14.52 | 1 x 4.3 mm | 4.3 | 5.7 | 0.7 | 140.21 | - | - | 700 | PVC Drum |

| 15.21 | 1 x 4.4 mm | 4.4 | 5.8 | 0.7 | 146.51 | 1.16 | 38 | 650 | PVC Drum |

| 15.9 | 1 x 4.5 mm | 4.5 | 5.9 | 0.7 | 152.95 | - | - | 650 | PVC Drum |

Goldengrip Winding Wires For Submersible Pump Motors

(Tested As Per IS 8783)

Stranded Conductor

| Copper Cross Section Area (mm²) | Conductor and No of Strands (Design) | Copper Dia. (mm) | Wire OD (mm) | Nominal Insulation Thickness (mm) | Total Weight/km (kg) | CR MAX at 20°C (Ohm/km) | Elongation (%) | Max Coil Length (m) |

| 10.03 | 19 X 0.82mm | 4.1 | 5.5 | 0.7 | 99.86 | 1.79 | 28 | 1000 |

| 12.09 | 19 X 0.9mm | 4.5 | 5.9 | 0.7 | 119.02 | 1.48 | 29 | 800 |

| 14.04 | 19 X 0.97mm | 4.85 | 6.25 | 0.7 | 137.17 | 1.28 | 29 | 700 |

| 14.92 | 19 X 1mm | 5 | 6.4 | 0.7 | 145.34 | 1.2 | 30 | 700 |

| 16.14 | 19 X 1.04mm | 5.2 | 6.6 | 0.7 | 156.62 | 1.11 | 30 | 650 |

| 18.06 | 19 X 1.1mm | 5.5 | 6.9 | 0.7 | 174.33 | 0.993 | 30 | 600 |

| 20.08 | 19 X 1.16mm | 5.8 | 7.2 | 0.7 | 192.99 | 0.893 | 30 | 500 |

| 22.94 | 27 X 1.04mm | 6.2 | 7.6 | 0.7 | 219.28 | - | 30 | 450 |

| 23.38 | 27 X 1.05mm | 6.26 | 7.66 | 0.7 | 223.35 | - | 30 | 450 |

| 25.66 | 27 X 1.1mm | 6.8 | 8.2 | 0.7 | 244.84 | 0.699 | 30 | 400 |

Note: Lesser and higher OD are available on demand.

Stranded Conductor

Note: Lesser and higher OD are available on demand.